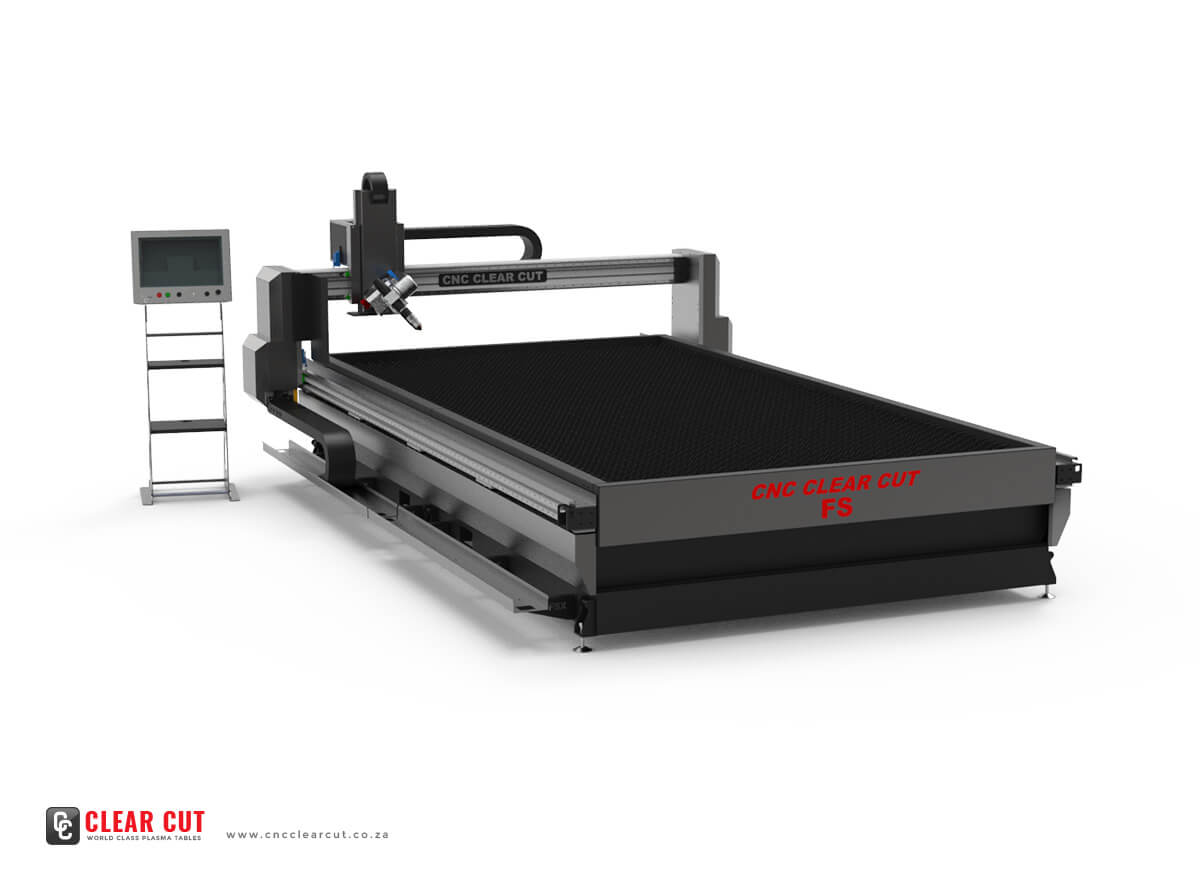

FS ADVANCED

HIGH DEFINITION PLASMA TABLEFor manufacturers with the most demanding production lines, our FS Advanced plasma table has the ability to elevate their business to new frontiers, combined with technologies like the XPR300.

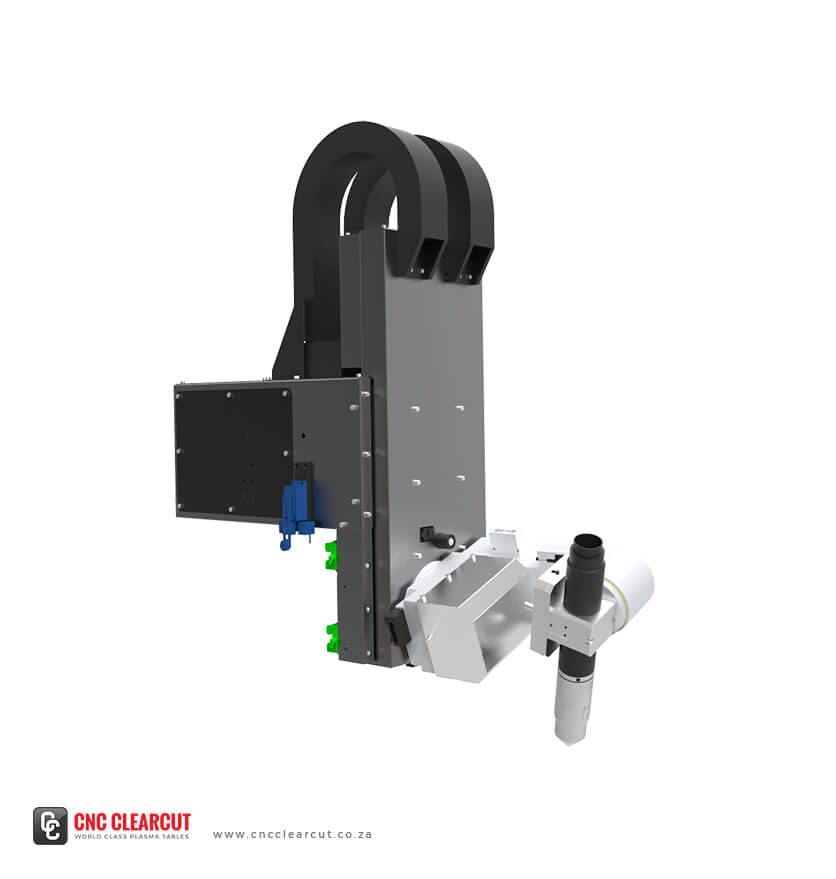

The FS Advanced machine comes standard with a water bed with sizes from 3000x1500mm to 4000x2000mm. The machine boasts cutting capabilities of up 50mm thick, advanced torch height control, laser plate alignment and various safety features. The FS Advanced is also equipped with True Hole, Rapid Parts and Scribing Technologies. As an Optional Extra, the Bevel Attachment can be added to the machine for True Bevel cutting.

AVAILABLE SIZES

| WORKING AREA |

|---|

| 3100x1600mm |

| 4100x2500mm |

PRODUCTION PIERCE

Dependant on plasma (Up to 50mm)

COMPATIBLE PLASMA UNITS

FEATURES

| Combats smoke pollution and material heat deformation |

| High accuracy |

| Advanced torch height control |

| Ohmic or Stall Force plate sensing |

| Laser plate alignment |

| Aluminum profile gantry for optimised acceleration, cutting speeds and cut quality |

| Safety: X & Y limit switches, Emergency stop, Torch collision magnetic break-away |

SPECIFICATIONS

| Waterbed |

| Working area: 4100x2100mm - 3100x1600mm |

| Controller: Edge Connect |

| Motion: Servo motor driven |

| Repeated Accuracy: ± 0.05mm |

| Rapid speeds up to 30000mm/min |

| Acceleration: Up to 80mG |

| Direct drive reduction planetary gearbox |

| Pressure loaded rack & pinion |

| High precision linear guides |

| Dual X-Drive gantry system |

| Plasma Range: HPRXD & XPR |